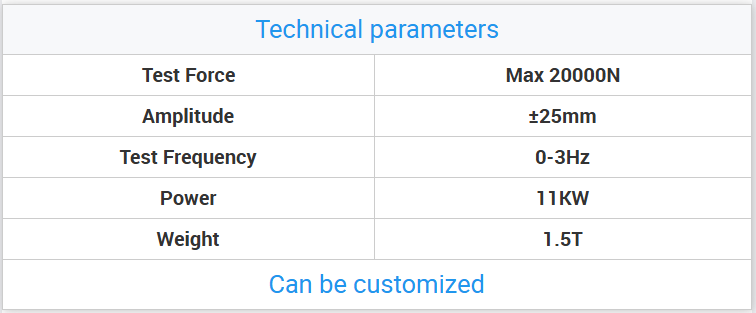

Fatigue Testing Machine

A shock absorber fatigue testing machine is a specialized piece of equipment designed to evaluate the durability and performance of shock absorbers under repeated stress over time. The primary purpose of this machine is to simulate the long-term operating conditions that a shock absorber would experience in real-world environments, ensuring it can withstand continuous loads, vibrations, and motions without failure.

The machine works by applying cyclic loading or motion to the shock absorber, replicating the repeated compression and extension movements that occur during normal use, such as when a vehicle goes over bumps or uneven surfaces. The shock absorber is subjected to these repetitive forces over thousands or even millions of cycles to determine its fatigue life—essentially how long it can perform effectively before showing signs of wear, degradation, or failure.

- 1. Who are we?

We are based in Zhejiang, China. We are CNC machining manufacturer with more than 30 years experience. We have more than 200 sets of machining equipments. We are IATF 16949 certified. There are total about 201-300 people in our factory.

- 2. How can we guarantee quality?

Inspection Equipment: CMM, projector, Rockwell Hardness tester, Coating thickness tester, Air gauge, Carbon Sulphur Analyser.

Always provide pre-production sample before mass production;

Always full dimensional final Inspection before shipment;

- 3. Why should you buy from us not from other suppliers?

We are a is a professional company with 20 years of experience working with OEM companies

We focus on quality.

We accept small orders

We have R&D Team

- 4. What services can we provide?

Accepted Delivery Terms: FOB,EXW;

Accepted Payment Currency:USD,CNY, EURO.

Accepted Payment Type: T/T;

Language Spoken:English,Chinese